Purlins

Purlins

Inovosteel Ltd. specializes in the production and supply of high-quality steel purlins, essential components for modern roofing and cladding systems. Manufactured using precision roll-forming technology, our purlins offer exceptional strength-to-weight ratio, corrosion resistance, and structural support for a wide variety of steel buildings and construction projects.

Whether used in industrial sheds, warehouses, commercial buildings, or agricultural structures, Inovosteel’s purlins are engineered to meet the highest standards of durability, cost-effectiveness, and performance. We offer both C-purlins and Z-purlins in various sizes and thicknesses, tailored to specific project requirements.

Technical Features:

C & Z Profile Options: Available in standard and custom sizes to match your design and load requirements.

High Tensile Steel: Made from high-quality galvanized or cold-formed steel for superior strength.

Lightweight Yet Strong: Reduces overall structural load while maintaining stability.

Precision Engineered: Consistent quality and dimensions for easy installation and structural alignment.

Corrosion-Resistant Coating: Galvanized finish ensures long life in both indoor and outdoor applications.

Cut-to-Length Fabrication: Supplied as per exact project dimensions to minimize waste and installation time.

Bolt & Screw Compatible: Designed for seamless integration with other steel components and roofing sheets.

Low Maintenance: Durable materials that require minimal upkeep over their lifetime.

Recyclable Material: Sustainable and eco-friendly, aligning with green building practices.

Flexible Application: Suitable for both primary and secondary framing systems.

Applications:

Industrial Sheds: Provides horizontal support for roofing sheets and panels.

Warehouses & Factories: Essential for large-span roofs and wall cladding support.

Agricultural Buildings: Used in barns, poultry houses, and greenhouses for structural framing.

Commercial Buildings: Integrated into steel framing for retail outlets, showrooms, and office structures.

Canopies & Awnings: Light framing applications where minimal weight and maximum durability are needed.

Solar Panel Mounting: Structural base for solar panel installations on metal roofs.

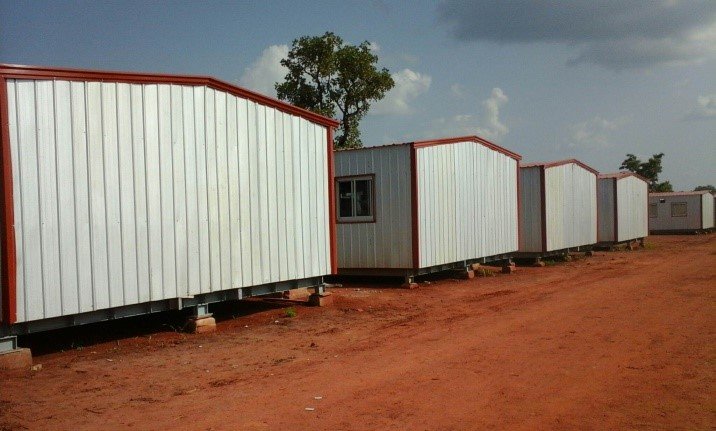

Temporary Structures: Quick-install support systems for prefabricated or modular units.

Build Better with InnovSteel!

Inovosteel Ltd. is a premier provider of pre-engineered steel buildings, founded with the aim of delivering superior steel construction solutions in Bangladesh and the surrounding regions.

Usefull Link

- Home

- Product

- Services

- Completed Project

- Ongoing Project

- Testimonial

Office Address

-

Corporate office:

Sundharam Plaza (3rd Floor) 20/3/A, West Panthapath, Dhaka-1205, Bangladesh -

Factory Address:

Vobani pur. Jell Khana Road, kashimpur Bazaar, kashimpur Gazipur- 1707, Bangladesh - Hotline: +88 01719-246836

Innovo Steel. All Rights Reserved © 2025